|

This

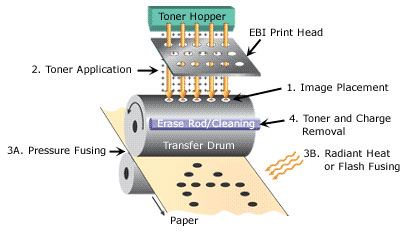

printing process consists of a series of four steps: This

printing process consists of a series of four steps:

Step 1: Image Placement - The EBI print head generates

controlled patterns of electronic charges on a

rugged, anodized aluminum transfer drum as the

result of the principle of corona discharge. The

corona discharge process is exceptionally fast

and reliable and similar in some ways to generation

of electrons by the sun in our solar system. There

is one electron beam dedicated to each dot produced

on the image, allowing the engine to operate at

very high speeds.

EBI printing is an efficient "write black" process

where the patterns of charges are applied directly

to the transfer drum. By comparison, electrophotographic

printers first charge the entire drum surface,

and in a second step, remove the charge. This

"write white" process requires sophisticated moving

optics that need frequent maintenance and service

when operated at very high speeds. EBI print engines

are in production and operating daily at speeds

in excess of 450 feet per minute without the complex

support requirements necessary for other digital

print engines.

Step 2: Toner Application - The charged surface

of the transfer drum that forms the latent image

attracts toner particles. EBI toner contains a

controlled percentage of magnetite the ingredient

use in toner for Magnetic Ink Character Recognition

(MICR) printing applications. Inherent in the

EBI printer engine design is the capability to

produce MICR output without complex toner reformulation.

A range of EBI toners are available with different

characteristics to satisfy a variety of applications.

Step 3A: Pressure Fusing - To fuse the toner

into the paper, a simple roller applies cold pressure

to transfer the toner to the paper. EBI print

engines normally achieve greater than 98% toner

transfer efficiency and do not require heated

fusing rollers or consume silicon oil. Cold pressure

fusing completely eliminates the nead for a "developer

station" in the print engine. There is no down-time

required to change the developer that is frequently

a maintenance issue with electrophotographic printer

engines.

Step 3B: Radiant Heat or Flash Fusing - Pressure-fused

EBI images are durable with high permanence. To

help sustain image integrity after rigorous handling

in post processing and mailing applications, a

secondary fusing process is completed before the

paper exits the printing system. A "flash" fusing

station is incorporated in RS Series printers

while continuous "radiant heat" fusion is applied

in the ultra high-speed CR Series.

Step 4: Toner & Charge Removal - To prepare the

transfer drum for the next print image, any residual

charge is removed by the "erase rod". This neutralizes

the surface of the transfer drum in preparation

for re- exposure to the print head. Any remaining

toner particles are removed from the drum by a

simple cleaning roller.

|

|